Customized Cable Assemblies - IMS CS

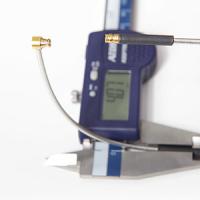

Coaxial RF Cable Assemblies

For us, cable assembly begins with the requirements of our customers - and ends with our own quality standards: everything from a single source! From prototyping to pre-series to series production.

From small, medium and large series, we assemble your HF solutions in stable series quality for a wide variety of sectors from industry and medical technology with pressure-monitored toggle presses and semi-automatic processing machines.

Wires, lines and cable harness assemblies

Wires, cables and cable harnesses are our daily business in cable assembly. Our extensive possibilities in the field of production (crimping, splicing, soldering and assembly technology) guarantee you high-end processing of your single strands, round, spiral, ribbon and foil cables, but also the complete assembly of your cable harnesses.

Your advantage - IMS CS cable assemblies

Our worldwide branches enable economically efficient solutions, from manual production with toggle presses to semi-automated production to fully automated production. The processing of individual strands is carried out on semi-automatic and fully automatic machines with integrated crimping force monitoring. Our portfolio includes contacts, connectors and cables from well-known manufacturers such as J.S.T., FCI, Molex, Hirose and others.

Flexible/semi-flexible cables with the best low-loss properties

Not designed for constant movements/loads, these cables surprise with the best technical properties. These cables are mostly used in the area of antennas, for TV transmission and more.

Semi-rigid cable for frequencies up to 40 GHz

These cables are mostly used in internal wiring areas and are found in high frequency equipment and wireless applications. The properties of the cable mean that it must be used with non-moving connections.

For routers and gateways - Hirose, muRata, I-PEX

Miniaturized pigtail U.FL, H.FL and I-PEX MHF are due to their Extremely small size has been in use for years. you are for ideal for a variety of applications where space is a critical factor is. The connectors work in a frequency range of up to 6 GHz and guarantee thanks to their low height of 2.5mm and a space requirement of only 3 mm² highest component density.

Classic vehicle wiring harness assemblies up to zonal architecture

Zonal architecture brings network topologies to automotive design.

This makes communication faster, cables shorter and, above all, it makes it easier to standardize and replace components.

We not only offer the right connector systems, but also develop suitable cable assembly solutions.

Individual processing for individual applications

Whether in vehicle construction, mechanical engineering, medicine, control technology or electromobility. Our services are as diverse as your area of application.

Ready-to-connect cables/cable bundles/cable harnesses

Robust insert moulding solutions, induction soldering and reflow soldering and/or sealing solutions using adhesive technologies for water, dust and helium are our daily business. 100% electrical and visual controls guarantee best RF performances up to 6GHz.

Tight bend radii? No problem!

Customized solutions are our strength. Cable geometries, the extremely tight bending radii are indispensable in modern applications, as the demands on space requirements are increasing. We can customize flat ribbon cables as well as spiral and round cables for your application.

Inexpensive and simple plug/solder connections with foil cable

In addition to our B2B connectors, we use foil cables for board-to-board connections using cables. These connections can either be soldered directly or fitted with sockets or pin connectors.

Fast, flexible and precise process

Our locations are designed to process customer orders quickly, flexibly, cost-effectively but with the highest quality standards. Harness assembly is no exception! Individual lines are bundled into cable harnesses and taken to the customer via the shortest possible route.

Cost efficient solutions for demanding customers

Cost-efficient solutions through manual over semi-automatic to fully automatic production are possible. Versatile sealing solutions from injection molding technology or innovative solutions for areas at risk of explosives are possible.